1、 Introduction

As an important component of electronic components,

Connectors are widely used in many aspects such as electrical circuits, electronic equipment, and various measuring instruments, playing a crucial role in information transmission and data exchange. The application forms of connectors are rich and diverse, and can be divided into several types according to their unique deployment methods. This article will provide corresponding explanations and explanations for these common types of connectors and their respective characteristics.

2、 Introduction to Classification Methods and Characteristics of Connectors

1. Screw connectors

Compared to threaded connectors, their structure is more complex, and their stability and smoothness are highly guaranteed. Although this type of connector must rely on specific tools to complete assembly work, which is obviously not suitable for ordinary users, it has won the love of electronic engineers with its excellent connection effect.

2. Snap on connectors

The snap on connector appears to be both fast and convenient during the connection process, with extremely high efficiency, and is highly favored due to its exquisite size. However, in terms of stability, it is slightly inferior to threaded connectors, which has become one of the main reasons limiting its large-scale application.

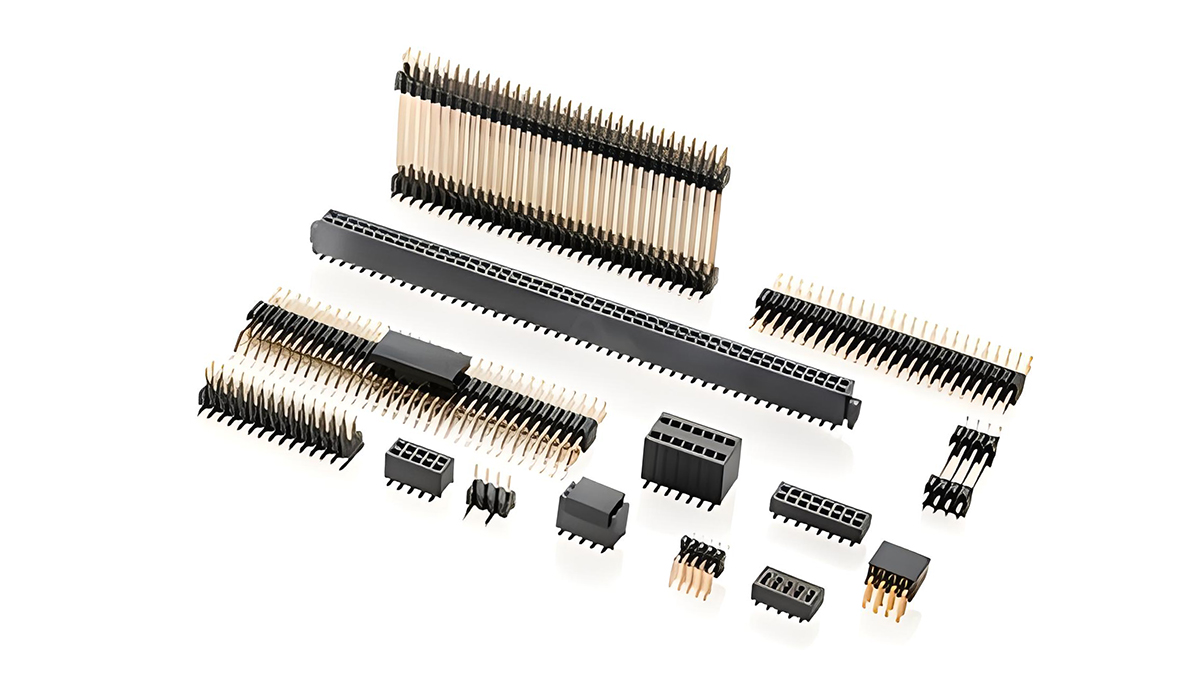

3. Pin connectors

Thanks to the efficient matching of pins and sockets, pin connectors have excellent repeated insertion and removal performance, greatly enhancing their guarantee of connectivity and stability. However, due to its relatively simple design, its stability may not fully reach the level of performance of threaded connectors.

4. Welded connectors

Solder connectors are commonly used to directly solder connectors onto circuit boards or other types of connectors, ensuring the strength and stability of the connection. However, this method often requires advanced professional skills and specialized equipment support, and may also cause damage to the circuit board or connectors, so it is not recommended for ordinary users to use it frequently.

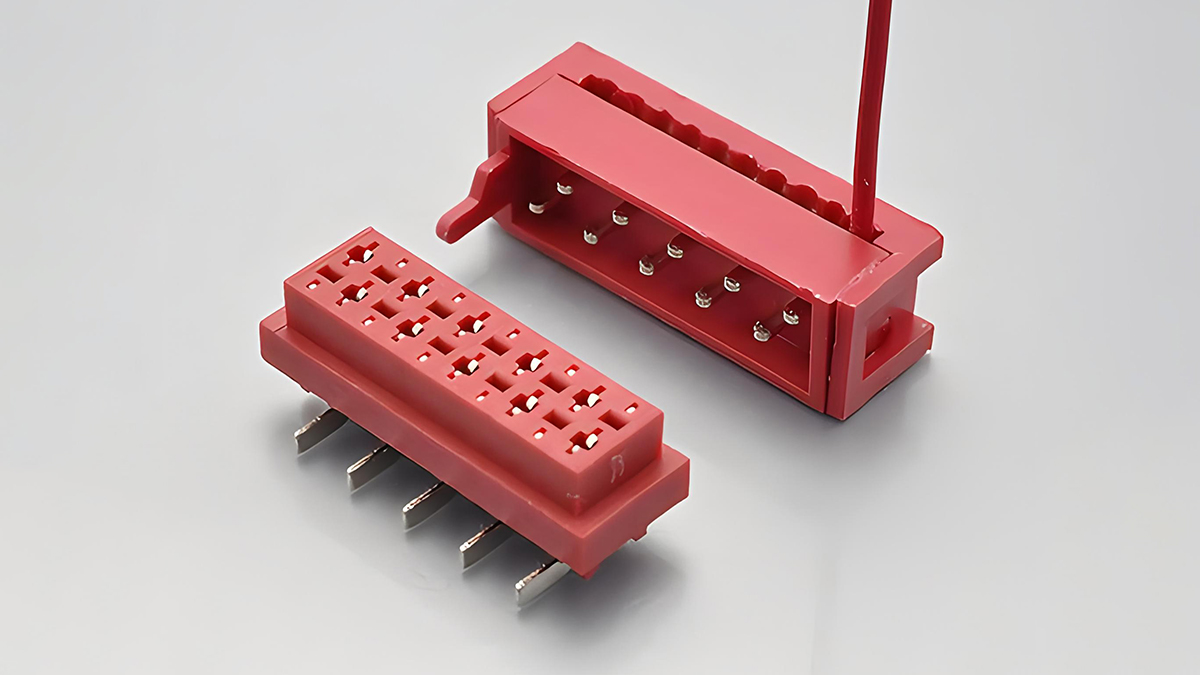

5. Crimp type connectors

Crimp connectors tightly connect the connector to the circuit board or other connectors by applying a certain amount of pressure, which not only ensures the stability and reliability of connectivity, but also has extremely high safety and reliability. Compared to welded connectors, crimp connectors tend to be a more ideal and safe choice.

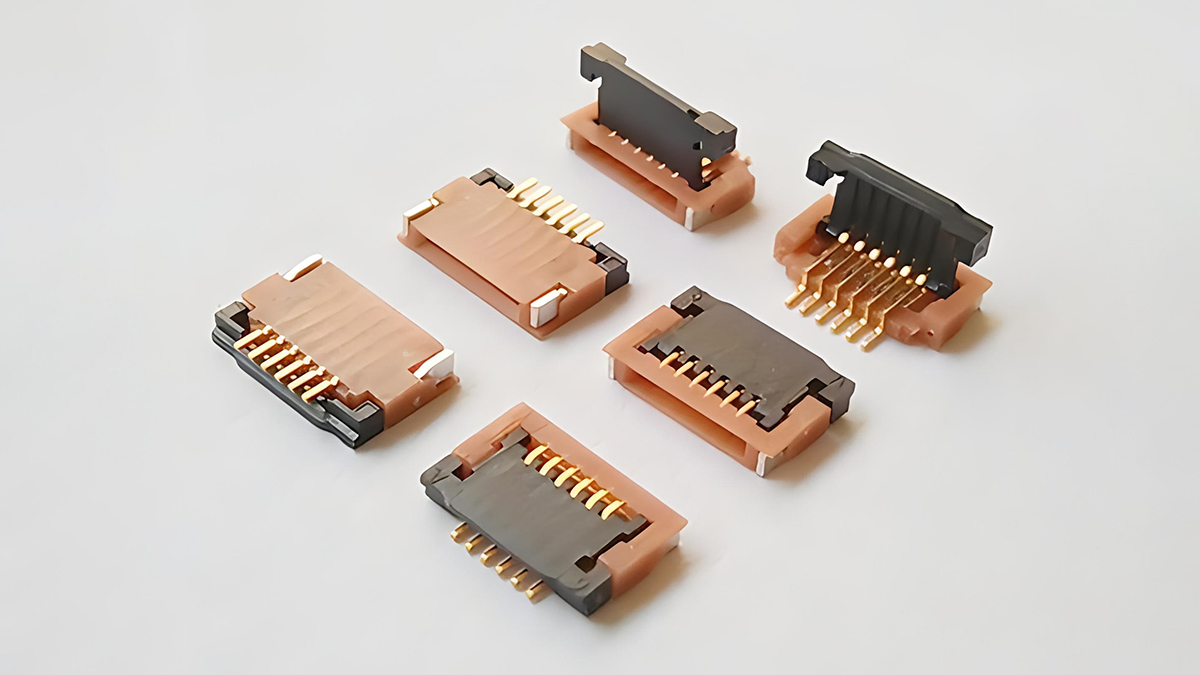

6. Floating connector

Floating connectors focus on solving the connection difficulties faced by a large number of connections between PCB boards. It can effectively avoid possible connection difficulties caused by differences in component distribution. However, due to its unique structural design, the connection stability is slightly insufficient compared to ordinary threaded connectors.

3、 Development trends and influencing factors of connectors

Based on the current market trends, we can foresee that in the coming years, connectors will further develop towards intelligence, high-performance, and lightweight, which has become one of the most concerning topics in the connector industry.

With the improvement of the intelligence level of connectors, they will have multiple functions such as intelligent communication, intelligent regulation, and intelligent monitoring, greatly enhancing the intelligent application value of connectors in various application scenarios.

2. With the continuous evolution of the social economy and the booming development of emerging fields such as 5G communication, Internet of Things, and artificial intelligence, the range of harsh working conditions that high-performance connectors can meet is also expanding day by day, especially with the increasing scale of circuits, high energy consumption, high voltage, high current, high-frequency signal and other application scenarios becoming more and more common.

3. With the increasing weight requirements of portable devices, achieving lighter connector design has become an important indicator for measuring the quality of a connector product. Lightweight connectors can not only reduce the overall volume of equipment and facilitate portability, but also have wide applications in specific fields such as mining engineering and aerospace.

4、 Conclusion

In summary, when selecting connectors, we need to comprehensively evaluate their quality from multiple perspectives such as connection stability, communication speed, pin connection method, and whether they support hot swapping. At the same time, in the selection process, full consideration should be given to factors such as current carrying capacity, internal structure size, signal interference suppression ability, mechanisms to prevent incorrect insertion, as well as the reliability and universality of connectors. When facing practical application scenarios, we should carefully select appropriate types of connectors based on specific needs and environmental conditions to ensure stable operation of the connected system and accurate information transmission.